Andrew Thompson BSc, CEng, MIChemE , Technical Director at Ronald Britton Ltd, gives an introduction to TÜV Austria OK biodegradable WATER – Fresh Water Biodegradable Certification and what it means for glitter.

Read More

Andrew Thompson BSc, CEng, MIChemE , Technical Director at Ronald Britton Ltd, gives an introduction to TÜV Austria OK biodegradable WATER – Fresh Water Biodegradable Certification and what it means for glitter.

Read More

Glitter Colour Effects – Playing with the ‘Physics of Light’ Over the years ‘glitter myths’ have developed. In this blog we aim to bust the myth of what’s behind the glitter colour effects. I’m sad to say it’s not ‘magic’, but something far more magical, the physics of light. Glitter effects can be grouped into […]

Read MoreBioglitter™ is designed to biodegrade quickly and safely in natural freshwater environments. Ronald Britton Ltd uses TÜV OK biodegradable WATER certification as a simple and clear means of communicating this fact to our customers. We have taken this approach as simple terms such as ‘100% plastic free’ and ‘100% biodegradable’ can be misleading, used without […]

Read MoreComposting and Microplastic Pollution It’s now well recognised that plastic glitter poses an environmental microplastic pollution issue. ECHA (European Chemicals Agency) has specified* freshwater biodegradability as a permitted test to establish whether a polymeric material is considered a microplastic. Fresh water biodegradability requires a significantly higher level of performance than composting. At Ronald Britton, we believe […]

Read More

TÜV, Austria, ‘OK biodegradable WATER’ Certification Products certified for OK biodegradable WATER are GUARANTEED by TÜV to biodegrade in natural, freshwater environments and thus substantially contribute to the reduction of waste in rivers, lakes or any natural freshwater. A level of certification considered the highest of its kind in the world THE CRITERIA REQUIRED TO BECOME CERTIFICATED: […]

Read More

Our Bioglitter™ products have won the Gold award for innovation at in-cosmetics global for two consecutive years, 2017 and 2018. We are especially proud of this achievement as it’s never been achieved by any other cosmetic raw material manufacturer. In 2019 we added to the awards cabinet with the accolade of ‘Green & Sustainable Fountain […]

Read More

EU Microplastic Regulation: A slow process, but clarity may be on the horizon Whilst the proposed EU restriction on intentionally added microplastics has been around for several years, there is still no firm date as to when it will come into force. The European Commission has now prepared a draft regulation and this needs to […]

Read More

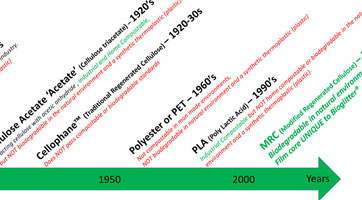

Cellulose is the substance that makes up most of a plant’s cell walls. Since it is made by all plants, it is probably the most abundant organic (carbon-containing) compound on Earth. Cellulose is a polysaccharide. A polysaccharide is a type of carbohydrate. All forms of ‘cellulose’ are NOT the same an have very different properties; […]

Read More

We supply Bioglitter™ in bulk packaging as a raw material for use by product manufacturers. We have a global raw material distribution network supplying Bioglitter™ products to specific industries. Click on the links below to be redirected to your relevant industry. Cosmetic & Personal Care Industry Decorative, Coating, Printing, Art&Craft, Household & Horticultural Industry Education and Retail Craft […]

Read MoreNo Bioglitter™ does not dissolve in water. Microorganisms found in the natural environment are needed to digest Bioglitter™ and transform it into harmless substances; carbon dioxide, water and biomass. No microbes = No biodegradation Dissolving and biodegrading are completely different. Something that dissolves does not go away, it’s still there in the water, it just […]

Read MoreBioglitter™ is very stable and will not biodegrade until its put into environments where microorganisms are present. Bioglitter™ as supplied in dry form, has an indefinite shelf life, providing it is stored in a dry, cool environment, out of direct sunlight, away from direct heat sources and not exposed to microorganisms. For good manufacturing practice […]

Read MoreAll Bioglitter™ products are non-toxic and pass:- EN71 European Toy Regulations, as detailed in the specific product information. Global Cosmetic Regulations, as detailed in the specific product information. All Bioglitter™ product ranges meet the ecotoxicity and heavy metals (13 heavy metals evaluated) for TÜV OK biodegradable WATER certification.

Read MoreWhat is a microplastic? A microplastic is a small piece of plastic, less than 5mm in size, made from polymeric materials that do not biodegrade quickly and safely in the natural environment. These can originate from; Secondary Microplastics – Larger plastic objects like bottles and other packaging that break down in terms of particle size […]

Read MoreThe reflective aluminium layer in Bioglitter™ SPARKLE and Bioglitter™ HOLO products has been optimised to be as thin as possible, 2500 times thinner than a human hair! Aluminium is a metal that’s found in the natural world, it’s the most abundant metal in Earth’s crust. Like water and minerals, metals are inorganic, meaning they don’t […]

Read MoreThe Cosmetic Bioglitter™ ranges supplied by Ronald Britton Ltd are produced using pigments that meet with the applicable purity criteria of: US FDA (21 CFR) China’s Cosmetic Safety and Technical Standard (2015 version) EU Cosmetic Regulation (EC) No. 1223/2009 & (EU) No. 231/2012 Japan – Ministry of Health, Labor and Welfare Ordinance No 126 of […]

Read MoreRonald Britton Ltd Bioglitter™ products comply with the requirements of the EU Toy Safety Directive: EN71-1:2014 Mechanical and physical properties EN71-2:2011+A1:2014 Flammability EN71-3:2019 Migration of certain elements EN71-9 Primary Aromatic Amines

Read MoreAntimony is a heavy metal used as a catalyst in the production of polyester and some remains after production in the polyester as an impurity. Antimony long term exposure can cause irritation and ultimately can cause more serious health effects. The total antimony level in Bioglitter™ is <0.5ppm (parts per million) evaluated by Inductively Coupled […]

Read MoreRonald Britton Ltd Bioglitter™ is defined as a finished article and therefore does not require registration under REACH. Article 3(3) of REACH regulation states – “article: means an object which during production is given a special shape, surface or design which determines its function to a greater degree than does its chemical composition”. Glitter clearly […]

Read MoreBioglitter™ non-toxic and non-harmful. However, Bioglitter™ is not a foodstuff and therefore not intended for consumption.

Read MoreBioglitter™ is free of the 14 common food allergens. None of our raw materials knowingly contain any common allergens and our manufacturing equipment is not used to produce any other products that contain allergens.

Read MoreThe Bioglitter™ products supplied Ronald Britton Ltd do not contain any ingredients listed as carcinogenic, mutagenic or toxic to reproduction according to annex VI of the CLP Regulation, registered under REACH (EC) 1907/2006 and/or notified under CLP (EC) 1272/2008.

Read More